Research

- Combination of macroscale and microscale evaluations for the joint interface using microscale cantilever bending test

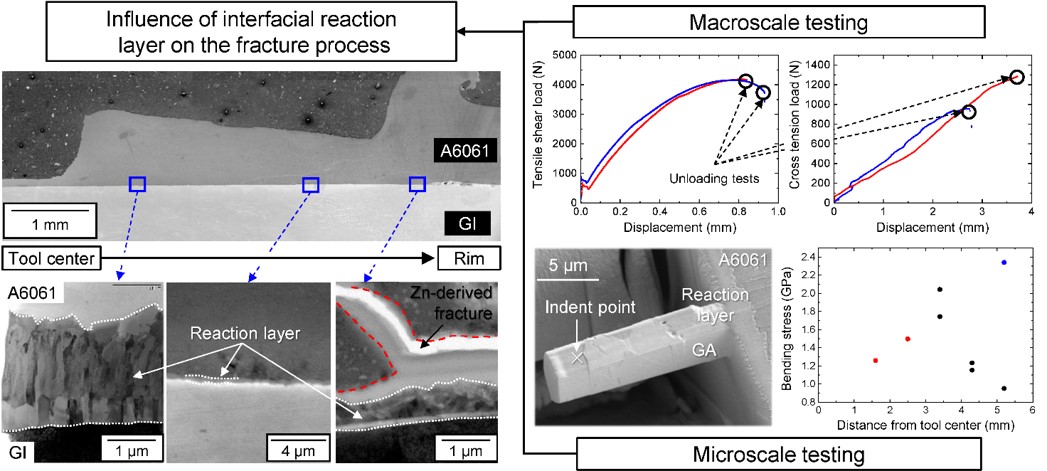

We demonstrated the influence of interfacial reaction layer on the fracture behavior of the friction stir spot welded dissimilar joints between galvanized steel and aluminum alloy through the microscale evaluation of interfacial strength in addition to the conventional macroscale evaluations. In particular, microscale cantilever beam bending tests showed that the interfacial strength increases with the decrease of reaction layer thickness except in the case of voids. Our study highlights the significance of rim region in spot welding, which has been indicated only by macroscale evaluations.

Paper:Materials Science and Engineering A, Vol.772, 138743 (2020).

- Microscale tensile test on the dissimilar joint interface

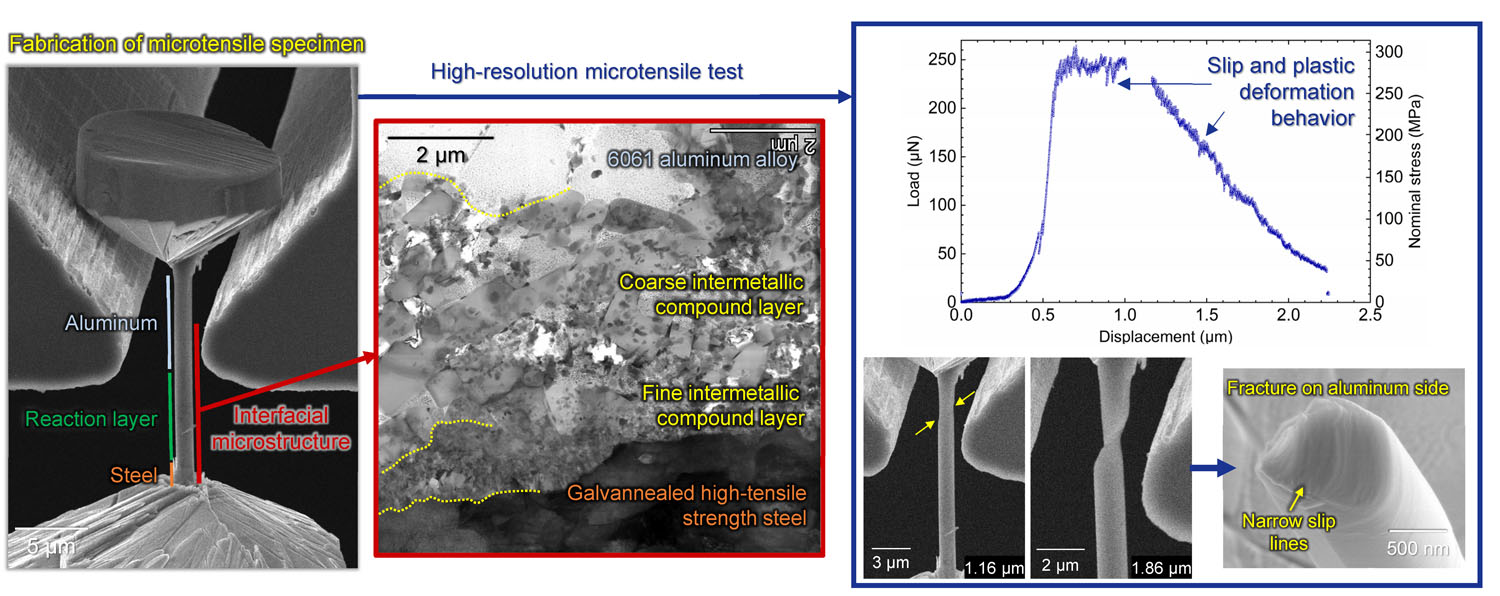

We developed a unique nano-microscale mechanical testing system for the evaluation of joint interface. Using this system, we succeeded in observing an interesting deformation behavior of microscale dissimilar joints for the first time.

Paper:Scripta Materialia, accepted (2020).

- Combination of experiment and multiscale simulations for the elucidation of bonding mechanism

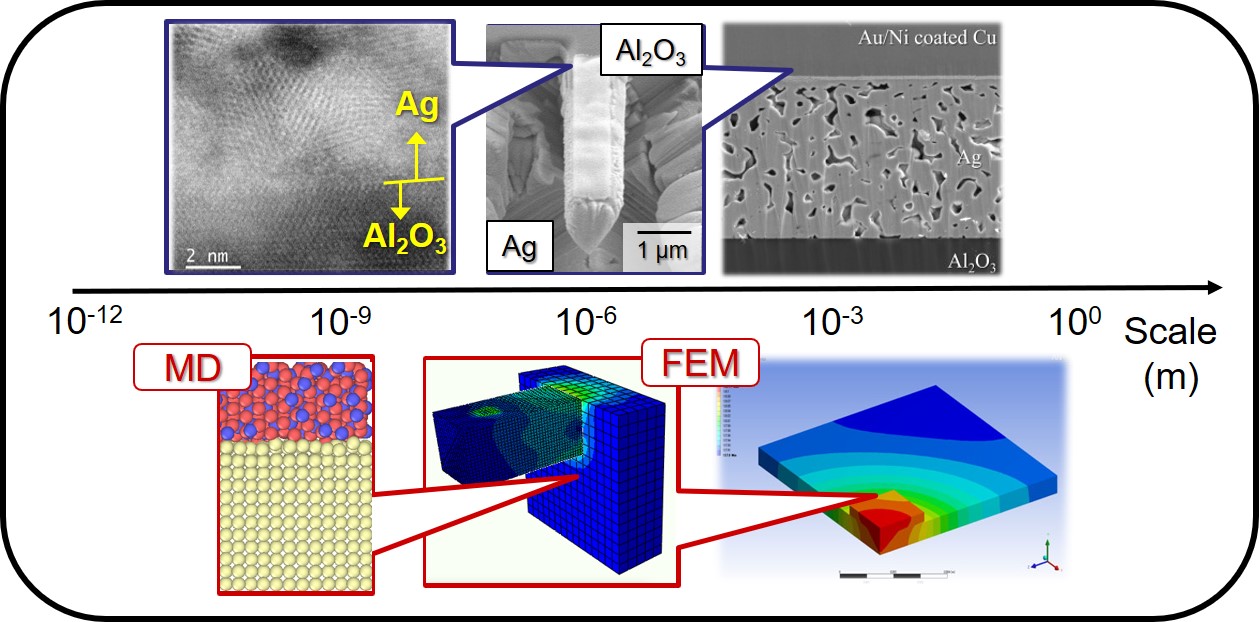

We investigate the bonding mechanism of dissimilar materials utilizing multiscale experimental evaluations and simulations such as FEM and MD.

Intelligent Manufacturing Process Area in Processing for Manufacturing

Division of Materials and Manufacturing Science

Graduate School of Engineering, Osaka University

Intelligent Manufacturing Process Area in Processing for Manufacturing

Division of Materials and Manufacturing Science

Graduate School of Engineering, Osaka University